The unique CALIPRI principle is a development of laser light section technology from non-contact demension and profile measurements.

GAP measurement and flush evaluation without aswswumptions

The systems in the CALIPRI C1X family measure gap and edge profile patterns without any extrapolation. Real data and color-coded gap width and flush offset provide a reliable basis for decision-making. Numerous patterns for measurement specifications and different model variants enable the cross-process application of a single technology.

Quick Profile and gap evaluation

The CALIPRI optical profile measurement device is suitable for profile measurements of individual components or for inspecting the dimensional accuracy of the complete unit. Compared to the sampling methods used in conventional measuring systems, the non-contact method delivers significantly more accurate and, therefore, reproducible measurement results.

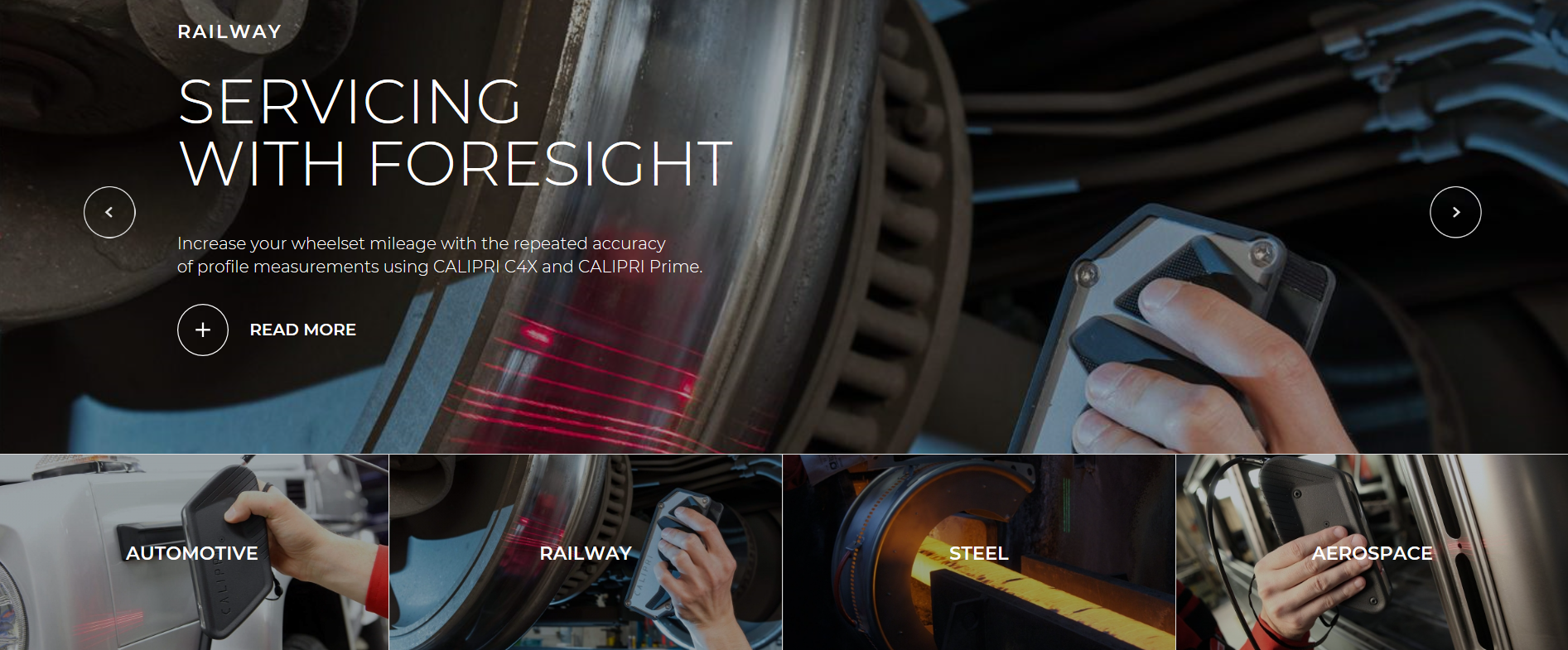

Highly precise profile measurements in the RAILWAY industry

CALIPRI non-contact profile measurement devices meet the demands of the railway industry with a reproducible and simple measurement method for the complete wheel-rail-system. Whether you are working with wheels, brakes, rails or switches – we have the right solution for any measurement task.

Identify surface defects and profile deviations

Forget about conventional approaches: In the future, carry out random sample measurements without delay using the portable profile measurement device CALIPRI RCX and, without an additional measuring system, evaluate cross sections and defects in one step with OSIRIS inspection systems. Both systems are based on non-contact measurement technology and obtain highly accurate measurement results.

NEXTSENSE RESPONDS TO NOISE REDUCTION IN GOODS TRANSPORT

The "Defects" CALIPRI C4X module helps users distinguish between critical and non-critical surface defects. Flat spots and spalling are evaluated with the non-contact measurement device, which is based on laser light section technology. An acoustic guide helps the user to position the measurement device. During the measurement operation itself, the sensor is simply aimed at the defect – there is no need to apply or precisely plot it. If there is a signal, it is a critical defect and the width and depth are calculated. After the measurement, the width and depth of the defect are shown on the sensor and the tablet PC and are automatically compared to the limit values entered.

NEXTSENSE passes the €10 million mark

Passing the €10 million barrier as early as the third quarter and winning the Fast Forward Award for the second time – NEXTSENSE reports economic successes for its 10th anniversary and has once again been given an award by the Styrian Business Promotion Agency (SFG).